People generally tend to use their tractor tyres as long as possible because it costs a lot to change them, and we all have other, more pressing financial priorities for our farms – fertiliser, seeds, cattle feed, fuel, and so on.

However, once they reach a certain level of wear your tractor tyres can represent a risk for you and your farm. Here are some tips to make sure they won't give up on you in the middle of a job:

You can choose to keep using your tyres until they reach the maximum amount of wear (which is the cheapest option), or you can replace them as soon as they reach the wear threshold stated by the manufacturer.

Generally when tyre is worn you easily feel it on the field on wet conditions. In this case, you note the increase of your slip ratio. If you go over 30%, buy new ones !

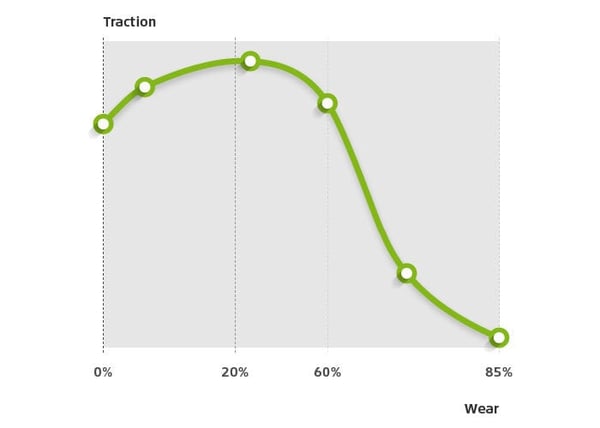

The first and easiest indicator of tyre wear is to measure the height of the lugs on the tread. Tyres are considered worn when the studs have lost 60% of their height compared to when new, which is when you will begin to lose traction power in transmission on filed use.

Don’t be surprise if you feel better traction on field at 20% wear is due to the fact you reach the perfect statement for traction on field. We estimate that after 85% the traction drop heavily. It means in general a minimum of 12mm front and 15mm rear, depending of work conditions.

indicator of tyre wear

The latter option may seem like a waste of money, but on closer inspection you'll see that it actually makes the most financial sense. By reselling your tyre for a good price on the second-hand market just as it hits the wear threshold and opting for a new tyre that preserves your soil and increases your machine's traction force, with the added benefit of reduced fuel consumption, you'll soon realise that the second choice is the best way to keep your productivity at its maximum.

For example, if the lugs are 60mm high on a new tyre, it will be considered as worn when they are 23mm or less. You'll get a good price for reselling a tyre with this level of wear on the second-hand market, which will then help offset the cost of a new set of tyres.

First of all, you should determine the cause of any uneven wear to prevent your new tyres from getting worn too quickly. There could be many reasons for uneven wear, such as a mechanical problem, steering, or tyre pressure. You can delay or prevent any future wear by identifying uneven issue and solve it rapidly thanks to visit of your local tyre dealer or manufacturer tyre specialist.

Don’t think you win money by using your tyre till the end because it could cost you a lot at the end:

To learn more and boost your farm's profits, Bridgestone Agriculture is offering you a free, detailed eBook that explains the essential role your agricultural tyres play in your productivity.

The most people who have read this article have also read the following articles, which are listed below in order of popularity:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

BRIDGESTONE EUROPE NV/SA

AG department

Kleine Kloosterstraat 10

1932 Zaventem, Belgium

Our regional office:

Athena Drive, Tachbrook Park

Warwick CV34 6UX

United Kingdom