Ballasting consists of increasing the weight of your tractor to improve tyre grip or lower its centre of gravity when working with heavy tools or high traction.

But what's the best form of ballasting?

Too much weight at the front could break the front axle assembly, whilst not enough weight can lead to excessive slip and slow down your work, as well as quickly wearing down your tyres.

Too much weight at the front could break the front axle assembly, whilst not enough weight can lead to excessive slip and slow down your work, as well as quickly wearing down your tyres.

As it turns out, ballasting your tractor tyres with water is still the simplest and most cost-effective way to ballast your tractor without mechanical risks.

In order to use heavy tools or have a high tractive force, when ploughing for example, you need to increase the weight of your tractor. A vehicle's traction capacity is directly correlated to its weight. Ballasting helps improve your tool's grip.

This reduces slip, which means less soil damage, more working efficiency (shorter working times), and longer-lasting tractor tyres (less lug wear).

This is therefore a particularly useful solution for jobs that require a lot of traction, especially when the ground is very wet and you're working with a high torque (ploughing), because the tractor needs to move forward without slip to avoid smoothing out the ground and compacting the soil.

You can detect excessive slip by observing the tracks left by your tyres on the soil. If the shape of the lugs is not clearly defined, or much thicker than the actual size of the lugs, it means there is too much slip.

Accumulation of earth between the tyre lugs is also a sign of high slip, resulting in a substantial loss of tractive force and therefore additional fuel consumption and premature tyre wear.

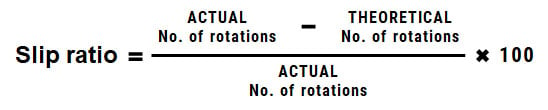

You therefore need to calculate the slip ratio to determine whether or not your tractor needs to be ballasted.

To do this, drive your tractor over a given distance (100 metres, for instance) while someone else counts the number of times the wheel rotates over this distance. Next, calculate the theoretical number of wheel rotations for that distance (distance travelled / wheel circumference).

Finally, use the following formula to obtain the slip ratio:

Ideally, this ratio should be between 12 and 15%.

Ballasting allows you to reduce your slip ratio by improving your tractor's grip and stability. This can be especially useful if your plot is on a slope.

The use of metal ballasts is recommended if you wish to modify the load distribution between the front and rear of your tractor, which is more difficult to achieve with water ballasting.

The use of metal ballasts is also more flexible, because you can adjust the number used based on the desired weight. However, installation is a very laborious procedure because it requires the use of lifting equipment due to the sheer weight of the ballasts.

To guarantee precision when adding weights, you should use a weighing device for each axle and check the tyre's maximum load index as recommended by the manufacturer.

Warning: some very heavy tools might still be too much for your tractor, even when ballasted. If this is the case, you may have to mount twin tyres to bear the weight and better distribute the tractive force.

If your tractor has to bear or pull a light load, most of its weight must be supported by the rear axle assembly. On the other hand, if the load is heavy, the weight must be distributed equally between the front and rear axle assemblies.

| Weight distribution between front and rear axle ASSEMBLY (%) | ||||||

|---|---|---|---|---|---|---|

| LIGHT LOAD | MEDIUM LOAD | HEAVY LOAD | ||||

| Front axle | Rear axle | Front axle | Rear axle | Front axle | Rear axle | |

| 2WD | 25% | 75% | 30% | 70% | 35% | 65% |

| 4WD | 35% | 65% | 35% | 65% | 40% | 60% |

The metal weights must be placed as low on the machine as possible to lower its centre of gravity and stabilise it.

Water ballasting is useful because it's cheaper and easier than ballasting with weights.

Water ballasting is useful because it's cheaper and easier than ballasting with weights.

Ballasting with water must be used the same as permanent ballasting if your tractor is too light for the work you want to do, but it does not allow you to rebalance the weight between the front and rear of your tractor.

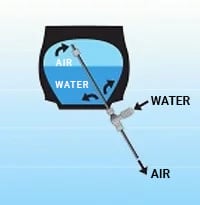

First of all, you must ensure that your tyres are compatible with water ballasting (check the information provided by the manufacturer). Most importantly, they must be equipped with an air/water valve.

As there is now less air inside the tyre, you will have to check the pressure more frequently. In addition, this will reduce shock absorption and comfort (which can be compensated for by the suspension) on roads in particular and will reduce your tractor's speed.

Before you ballast your tyres, always refer to the manufacturer's instructions on the filling procedure (see the filling volume table below):

| TYRE DIMENSIONS | LITERS (kg) | TYRE DIMENSIONS | LITERS (kg) | |

| 200/70 R 16 | 35 | 380/85 R 30 | 220 | |

| 240/70 R 16 | 40 | 420/70 R 30 | 225 | |

| 260/70 R 16 | 45 | 420/85 R 30 | 270 | |

| 265/70 R 16 | 45 | 460/85 R 30 | 340 | |

| 285/80 R 16 | 60 | 480/70 R 30 | 275 | |

| 425/55 R 17 | 95 | 495/70 R 30 | 300 | |

| 505/50 R 17 | 145 | 540/65 R 30 | 330 | |

| 280/70 R 18 | 55 | 600/65 R 30 | 440 | |

| 325/70 R 18 | 82 | 600/70 R 30 | 490 | |

| 355/60 R 18 | 102 | 710/60 R 30 | 600 | |

| 365/70 R 18 | 105 | 270/80 R 32 | 100 | |

| 275/80 R 20 | 65 | 300/85 R 32 | 140 | |

| 280/70 R 20 | 60 | 320/90 R 32 | 150 | |

| 280/85 R 20 | 65 | 650/75 R 32 | 570 | |

| 300/70 R 20 | 70 | 680/85 R 32 | 810 | |

| 320/70 R 20 | 80 | 800/65 R 32 | 740 | |

| 335/80 R 20 | 105 | 900/60 R 32 | 1030 | |

| 360/70 R 20 | 105 | 380/85 R 34 | 240 | |

| 365/80 R 20 | 135 | 420/85 R 34 | 290 | |

| 375/70 R 20 | 120 | 460/85 R 34 | 380 | |

| 380/70 R 20 | 120 | 480/70 R 34 | 310 | |

| 405/70 R 20 | 140 | 480/75 R 34 | 335 | |

| 425/75 R 20 | 150 | 520/70 R 34 | 355 | |

| 280/85 R 24 | 85 | 540/65 R 34 | 360 | |

| 320/70 R 24 | 100 | 600/65 R 34 | 465 | |

| 320/85 R 24 | 115 | 340/85 R 38 | 215 | |

| 340/85 R 24 | 140 | 420/85 R 38 | 320 | |

| 360/70 R 24 | 125 | 460/85 R 38 | 420 | |

| 380/70 R 24 | 145 | 480/70 R 38 | 340 | |

| 380/75 R 24 | 155 | 520/70 R 38 | 395 | |

| 380/85 R 24 | 185 | 520/75 R 38 | 420 | |

| 405/70 R 24 | 155 | 520/85 R 38 | 530 | |

| 420/70 R 24 | 170 | 540/65 R 38 | 420 | |

| 420/85 R 24 | 240 | 580/70 R 38 | 550 | |

| 440/65 R 24 | 185 | 580/75 R 38 | 590 | |

| 445/70 R 24 | 205 | 600/65 R 38 | 500 | |

| 480/65 R 24 | 210 | 650/65 R 38 | 630 | |

| 480/70 R 24 | 225 | 650/85 R 38 | 900 | |

| 480/75 R 24 | 240 | 710/70 R 38 | 800 | |

| 495/70 R 24 | 260 | 900/60 R 38 | 1200 | |

| 500/85 R 24 | 310 | 300/95 R 2 | 185 | |

| 540/65 R 24 | 300 | 460/85 R 42 | 460 | |

| 280/85 R 28 | 100 | 520/85 R 42 | 580 | |

| 320/85 R 28 | 130 | 650/65 R 42 | 650 | |

| 340/85 R 28 | 160 | 380/85 R 46 | 330 | |

| 380/70 R 28 | 165 | 460/85 R 46 | 500 | |

| 380/85 R 28 | 205 | 520/85 R 46 | 620 | |

| 420/70 R 28 | 200 | 270/95 R 48 | 150 | |

| 420/75 R 28 | 220 | 340/85 R 48 | 230 | |

| 420/85 R 28 | 250 | |||

| 440/65 R 28 | 200 | |||

| 480/65 R 28 | 250 | |||

| 480/70 R 28 | 260 | |||

| 480/75 R 28 | 280 | |||

| 540/65 R 28 | 315 | |||

| 600/65 R 28 | 400 |

|

If the footprint is not clearly defined: it means there is too much slip and your tractor has still not been ballasted enough. |

|

If the footprint is too deep: there is very little slip but too much compaction. |

|

Ballasting is adequate: when you see well-defined edges on the tyre footprint. |

To learn more and boost your farm's profits, Bridgestone Agriculture is offering you a free, detailed eBook that explains the essential role your agricultural tyres play in your productivity.

The most people who have read this article have also read the following articles, which are listed below in order of popularity:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

BRIDGESTONE EUROPE NV/SA

AG Department

Leonardo Da Vincilaan 1

1930 Zaventem | Belgium

Our regional office:

Athena Drive, Tachbrook Park

Warwick CV34 6UX

United Kingdom