Optimising spending is a major challenge for your activity’s profitability. This optimisation needs to go beyond negotiating the purchasing price of your machinery and consider the running costs which can be greatly reduced by improving the management of your equipment.

By paying attention to your tyres, you can improve the productivity of your machines, optimise fuel consumption and protect your soil.

Here are some guidelines that your can apply every day to get the most from your tyres and improve your farm’s productivity.

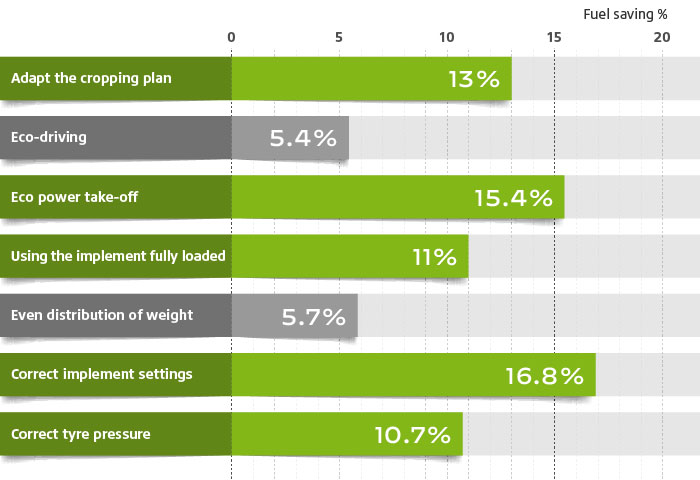

Fuel consumption is one of the cost items of your farming activity on which you can have an impact. This cost item can reach up to 20% of your operating costs.

You can reduce fuel expenses by adopting some good habits while using your tractor.

The first thing to do to reduce your tractor’s fuel consumption is to reduce your speed when driving on road surfaces. By reducing from 50 to 40 km/h, you may take 5 to 10 minutes more to complete the trip between your fields and your farm, but you will also save a lot of fuel.

There are several tractor models with a 40 km/h economy option enabling you to reduce fuel consumption during your trip by up to 30%.

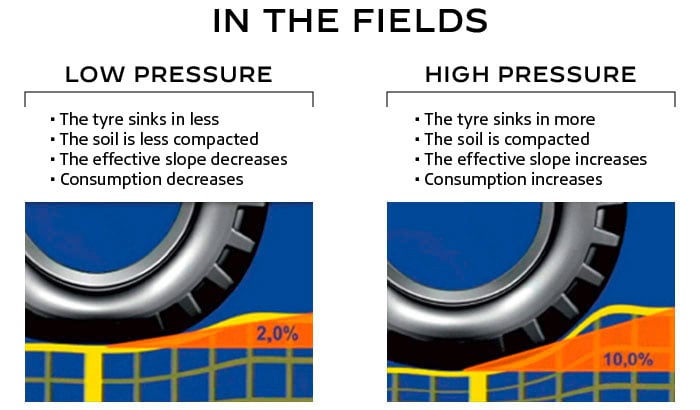

Adapting the tyre pressure to the type of soil is essential to optimise grip and reduce rolling resistance. There is no need to use high engine speed.

When the tyre is over-inflated, spinning is increased which makes it necessary to accelerate to achieve the same tractive force, greatly increasing fuel consumption.

In contrast, with a lower tyre pressure, the surface contact with the soil is increased and the lugs will have a greater bearing surface, traction is improved without increasing the engine speed.

To save time checking pressure and adapting it to the soil, use a central tyre inflation system which enables you to adjust the tyre pressure without leaving the driving cabin.

When you use a tool on a recent tractor model, you connect the power take-off which transmits the engine power to the tool.

When your activity does not require full power, for spraying for example, switch to economical power take-off. This mode reduces the engine power to the working power required which will be around 1600 instead of 2000 rpm in normal mode. This can reduce your fuel consumption by up to 20%.

In many cases, it is not necessary to plough deep down to provide the aeration required for good plant development.

If your fields are worked regularly and you use low pressure tyres on all your machinery, choose the minimum ploughing depth for each crop variety.

Adapt your ploughing machinery to plough just the upper soil layer. By digging les deep, you will require less engine force and consume less fuel.

Your tractor’s engine power is transmitted to the soil through your tyres. Optimising your tractive capacity means adapting the capacity of your tyres to the environment (hard, loose, wet… soil) to get the maximum benefits from your machinery and improve your productivity.

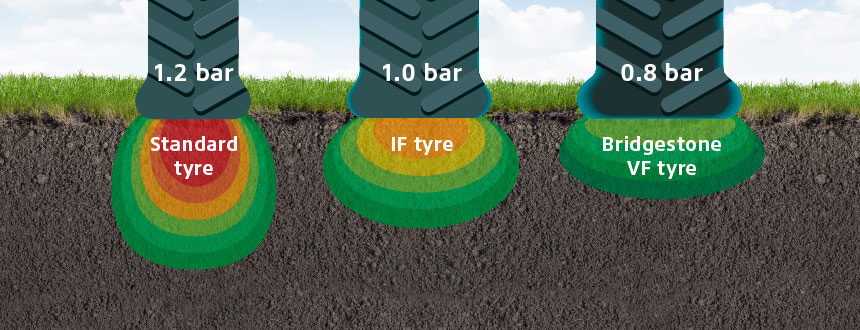

Generally, the original tyres on your tractor are standard tyres, as they are the most affordable for the manufacturer. They are not specially designed for heavy loads, if your machinery is heavy, you will need to increase the pressure to enable these tyres to carry the weight of your tractor. This will result in a drop in efficiency which will not only increase spinning, but will also increase soil compaction in your fields, and have a negative impact on driving comfort. Over inflated tyres absorb less vibrations.

If your machine is powerful, and therefore heavy, choose larger, low pressure tyres which can carry a heavier load. These tyres are particularly well suited to working in the fields, harvesting tools and transport.

As well as carrying a heavier load without requiring over-inflation, wider tyres distribute the tractor’s weight over a larger ground surface, improving your tractive capacity.

Using dual wheels provides the same advantages as wide, low pressure tyres. By putting two tyres together, the weight of the machinery is better distributed on the ground. You can reduce the tyre pressure while increasing the tractor’s tractive capacity.

Dual wheels have more lugs making them grip the soil more efficiently.

When pulling a large mounted or semi-mounted tool, the load greatly impacts the rear axle of your tractor. It is necessary to balance the masses to distribute the weight between the front and rear wheels. This balance is important to better distribute the weight on the soil.

While trying to achieve a good preponderance which enables the axles to be perfectly synchronised, you can put 40% of the load on the front and 60% on the rear. Using a front mounted tool to balance the whole convoy can be more effective than using weights.

Analysing the spin ratio is the best way to be sure of the tractive efficiency of your machine. If the footprint left by the lugs is not visible on the soil, or if the tracks are much larger than the actual size of the tyres, your tractor is slipping too much. It might also be that too much soil is accumulating between the lugs and the tyre’s self-cleaning capacity is not optimal.

This excessive spinning not only reduces your tractor’s productivity, but it also causes increased damage to your tyres, which will cost you more in the long term.

If you have any doubts, you can measure your spin ratio. To do this, count the number of rotations made by your tyres over a given distance and divide this figure by the theoretical number of rotations indicated by the constructor. By multiplying this result by 100, you will find the spin ratio. Above 15% the ratio is excessive.

If the spin ratio is high, reduce the tyre pressure or ballast the tractor to increase the tractive capacity. You can do this with metal weights or by adding water to tyres in compatible models. In both cases, the tyres will grip better and improve your tractive capacity.

Compacted soil will be difficult to work on and will not enable your crops to achieve an optimal yield. While taking care to save on fuel and optimise your tractive force, it is also vital to inspect your soil to see if it has been compacted by your machine. You could lose between 20 to 50% of your production.

You must inspect your soil regularly to check the compaction level. Certain warning signs could push you to carry out this analysis immediately. Firstly, if you notice numerous puddles in your fields, the soil is probably compacted and is not allowing the water to filter down to the lower layers.

Irregular crop growth is also a sign of compaction, while reducing the earth’s natural biological activity.

In non-compacted soil, roots should develop in all directions. In compacted soil, the roots will develop vertically or in just one direction due to poor soil aeration. Confirm the compaction of this part of the field by checking a neighbouring group of plants.

When the soil loses its crumbly structure, your yield will be considerably reduced. A chalky soil is generally more sensitive to compaction, but silty soil can also be compacted more moderately.

The first way to avoid soil compaction is to use the right tyre pressure to avoid excessive weight transfer from the machine to the ground. If the wheels cannot carry the load at the nominal pressure, it is advisable to reduce the load carried. If this is not possible, investigate dual-wheels or large, low pressure VF tyres.

Choosing the right period to carry out a task can also reduce soil compaction. You should plough during dry periods as wet soil is more sensitive to compaction.

It is also advisable to optimise the task calendar to avoid driving too often over the same field.

For ploughing, sewing, spraying or harvesting, place markers to avoid always driving over the same tracks. There is a system called Controlled Traffic Farming which optimises the passage of wheels on the ground to be worked.

Download the results by clicking on the button below

The most people who have read this article have also read the following articles, which are listed below in order of popularity:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

BRIDGESTONE EUROPE NV/SA

AG Department

Leonardo Da Vincilaan 1

1930 Zaventem | Belgium

Our regional office:

Athena Drive, Tachbrook Park

Warwick CV34 6UX

United Kingdom