A tractor wheel is a complex combination of numerous components providing it with both the rigidity and tyre-to-ground contact adapted to its use.

The radial structure is currently more widely used in the farming industry (IF VF technology) than the diagonal structure.

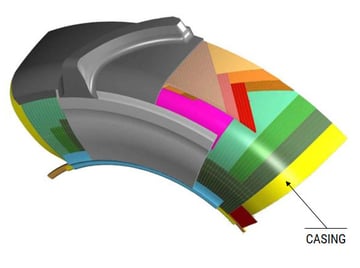

The structure of a tyre starts with its casing.

This casing is a mixture of synthetic textile cords and steel wires covered in brass and plaited together. Its job is to withstand the load that an agricultural tyre has to bear.

The casing of radial tyre

The orientation of these cord layers determines the type of tyre.

For a radial tyre, they are organised perpendicularly in relation to the running direction.

This positioning allows for increased deformability of the sidewalls, specific to radial tyres.

Shocks are better absorbed, and the comfort level is higher.

In addition, the internal surface of the casing is covered with a layer of rubber which has been treated to guarantee the water tightness of the tractor tyre and to maintain the pressure level.

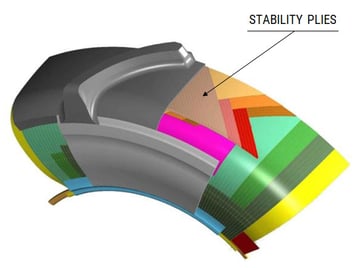

On the upper part of the casing, additional layers are placed diagonally to the running direction, they are the stability plies.

Stability plies of radial tyre

There are two types of plies:

Their job is to provide directional stability and to enable the tyre structure to work across its full width.

They also absorb some knocks and protect the casing from external damage.

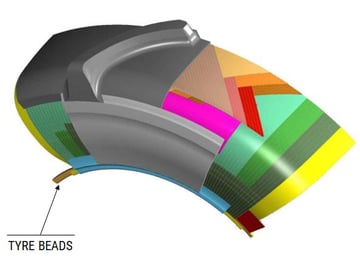

The casing is reinforced at the joint with the wheel rim, by metal rings (one on each side of the tractor wheel), known as tyre beads.

Tyre beads of radial tyre

These beads maintain the casing plies by stiffening the bead heel for good guidance of the tyre and high-quality transmission of traction between the rim and the tyre.

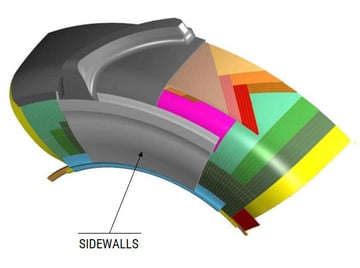

The external surface of the agricultural tyre is completely covered in rubber, this is the visible part of the assembly.

The resistance of this rubber to wear and cuts protects the casing and the plies from external damage.

The sidewalls of radial tyre

A thin and smooth layer is first placed on the sidewalls.

It provides the tyre with flexibility and works with the casing to absorb shocks.

The sidewalls also play a role in the lateral stability of the tyre.

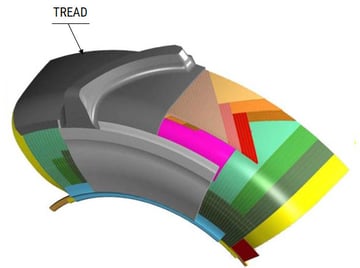

The tread is then placed on the external surface of the tyre. This is a thick layer of rubber, moulded during the vulcanisation process to form lugs.

Tread of radial tyre

The main role of these lugs is to provide traction whatever the conditions in which the tyre is used. To achieve this, their shape, angle and position are optimised.

The lugs also stabilise the tractor during manoeuvres. The tread also contributes to the driver’s comfort.

To take it one step further and increase the profitability of your farm, pneu tracteur provides a free, highly detailed eBook which explains the essential role of the agricultural tyre in your productivity..

The most people who have read this article have also read the following articles, which are listed below in order of popularity:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

BRIDGESTONE EUROPE NV/SA

AG Department

Leonardo Da Vincilaan 1

1930 Zaventem | Belgium

Our regional office:

Athena Drive, Tachbrook Park

Warwick CV34 6UX

United Kingdom