Using your normal agricultural tyres on unsuitable terrain can end up costing you a lot of money. Forestry work is highly specific and requires the use of special tyres.

The working conditions in forest environments are particularly tough on tyres, and are very different from the conditions met in the field.

Forest terrain is often soft and wet, therefore requiring significant traction for machines to drive through. As such, your tyres, and the lugs in particular, come under a lot of strain.

The ground may also be rough and damaging to your equipment due to the presence of branches or rocks (flint for example). Standard agricultural tyres, designed to limit compaction, are too flexible and too fragile, and therefore not adapted to such harsh conditions. That's why tyres specifically manufactured for "forestry use" must be used.

Usage conditions of forestry tyres

These tyres have been specially designed to cope with the demands of forestry environments.

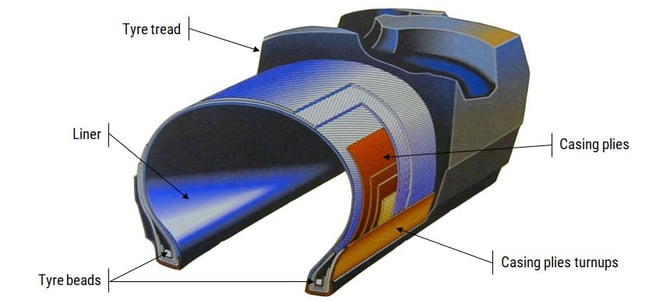

Steel casing plies have been added to consolidate the structure, and nylon plies improve resistance to moisture. In addition, the bias ply structure offers better stability, which is valuable when the ground is sloped or rugged.

Forestry tyre

The rubber layer on the tread and sidewalls is also 20% thicker than it is in standard tyres, which also helps protect the tyre, especially against punctures. The lugs are deeper to improve the traction capacity. The Bridgestone Forestry tyre is an example of this type of tyre (see below).

The main difference between forestry tyres and other agricultural tyres lies in their structure. Most agricultural tyres have a more flexible radial structure to prevent excessive soil compaction, whilst many forestry tyres use a bias ply structure reinforced with steel casing plies (see below), which is more suitable for their usage conditions.

The intersecting arrangement of casing plies, angled at 45° to their direction of travel, gives bias tyres greater rigidity, especially on their sidewalls, which makes them more resistant to external damage (by branches or stones, for example).

If your tyres are not well suited to the terrain, there is a substantial risk to your equipment as well as to your personal safety. Debris, stones or impacts could tear the sidewalls if they're not reinforced enough. Forestry tyres are often equipped with a protective bead to further reinforce the beads and sidewalls against impact and scratches.

Sidewall on a standard tyre, torn after impact with an obstacle

In addition, there is significant shearing force acting on the lugs due to the high traction needed for forestry work. This force can lead to cracks or cuts on the lugs if the tyres are not adapted to the terrain. You therefore run the risk of damaging your standard equipment.

Cracked tread due to excessive shearing force

After some time, the weakened rubber may come away completely. The tread surface will therefore no longer be uniform, which could cause vibrations that adversely impact your comfort while working and the life span of your equipment.

Although strength is one of the most important criteria when choosing a forestry tyre, soil preservation must also be taken into consideration. Groundwork is often impossible in forest settings. Forestry tyres can generate a larger tractive force, thereby reducing slip and shearing of the soil layers.

As with a standard tyre, you must also pay attention to the working pressure (to find out more, see the manufacturer's table).

To go further and increase the profitability of your farm, Bridgestone-agriculture offers you a very detailed free eBook that explains the essential role of the agricultural tire on your productivity.

The most people who have read this article have also read the following articles, which are listed below in order of popularity:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

BRIDGESTONE EUROPE NV/SA

AG Department

Leonardo Da Vincilaan 1

1930 Zaventem | Belgium

Our regional office:

Athena Drive, Tachbrook Park

Warwick CV34 6UX

United Kingdom