Your tractor tyres are an expensive investment, but vital to the running of your farm. It is essential to manage them correctly to make them last for as long as possible and to enable you to make savings over the long term.

Beyond choosing the most suitable model for your needs, using them correctly and maintaining them regularly are also important means of saving money.

The tractor tyres installed by manufacturers are never the most optimal models, they are simply the most economical option for the manufacturer.

They do not take account of the weight of your tools, which vary from farm to farm. Before purchasing your new machinery, you can negotiate with the retailer to replace the standard tyres with the ones you have chosen, this is the best time to get a good price.

You can also wait until the original tyres have worn down to replace them with a model better suited to your use.

To ensure that your new tyres are a profitable investment, experts will generally steer you towards larger models if you work mainly in fields.

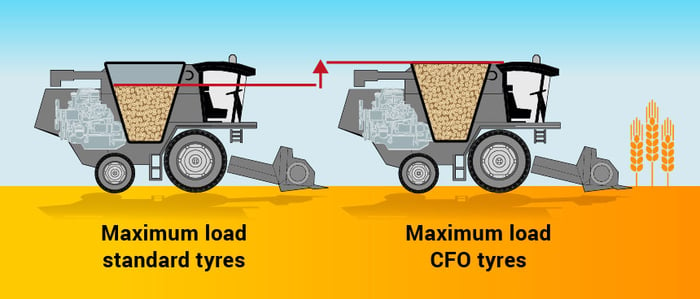

The first key advantage to larger tyres is that they enable your machinery to carry a heavier load. This load capacity is proportional to the volume of air contained in the tyre. Increasing the volume of the tyres allows you to use heavier and wider machinery which is generally more efficient.

A tractor with suitable large tyres can tow 35% more weight than with the original tyres. However, it is also important to look at the tyre brand, as a cheap tyre from an unknown brand will not be as efficient as an equivalent tyre from a renowned brand. The latter benefits from high standard of research & development and expertise resulting in its superior performance.

At the same time, you can choose the minimum recommended size of sidewall to increase the pneumatic capacity of each tyre (volume of air). The NRO standard (Narrow Rim) allows you to fit larger tyres to standard sidewalls. This will avoid the added expense of buying new sidewalls.

If you don’t have too long a drive on the road between your farm and your fields, it could be a good idea to look into IF (Increased Flexion) or VF (Very Increased Flexion) tyres.

The particularity of these tyres is that their sidewalls are flexible. With heavy loads, they will flex and increase the surface contact with the soil so that the weight of the harvester or tractor, and its tools, is better spread out on the soil, avoiding excessive soil compaction.

Tyres with the VF label can be used with a pressure of 0.8 bar and are particularly well suited to loose soil and ploughing, while providing increased traction. The VF tyre was designed to maintain the same pressure when driving on roads, so you no longer need to spend time adapting the tyre pressure.

As well as the IF and VF references which indicate sidewall flexibility, you should be aware of a few additional references to identify the tyre which is best suited to your needs.

The indication CFO (Cyclic Field Operation) relates to tyres that can carry a heavier load during a specific period.

They are particularly useful for harvesting machines which are used with huge variations of load during the harvest.

Caring for your tractor tyres is the best way to make them last longer. This way you can get the best return on your investment. Day to day habits, but also specific actions for each season to optimise the life span of your tyres. Here are a few examples:

If your tyres are highly solicited in the fields, in particular when they have to pull heavy machinery, it is possible to protect them when used on the more abrasive road surfaces. You simply need to drive more economically:

By following this advice, you will not only save fuel, but also protect your tyre rubber. When driving fast, the lugs wear down on the tarmac.

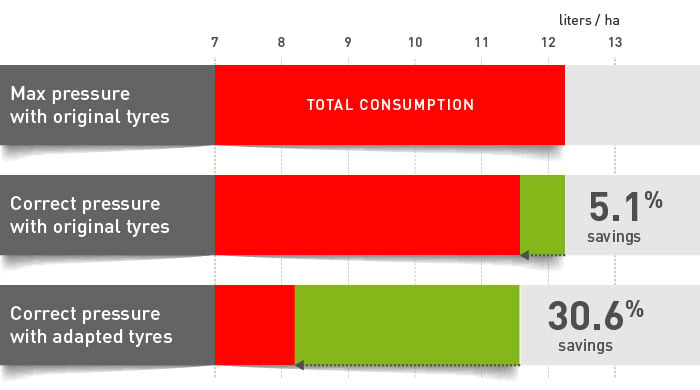

Managing the pressure depending on the surface to be worked is the best guarantee of the durability of your farming tyres. Incorrect pressure is the first cause of wear to rubber.

In the fields, it is essential to use the lowest pressure possible for your tyres to maximise the contact surface and transmission of tractive force and to avoid soil compaction.

When driving on road surfaces with low tyre pressure, you will not only wear out the rubber, but also damage the internal tyre structure. On the other hand, with a high pressure on loose soil, you will spin more.

Central tyre inflation system

While it is time consuming, it is essential to check tyre pressure when changing from road to field surfaces and vice versa.

Using a central tyre inflation system, in just two minutes you can adjust the pressure. Your tyres will last 25% longer.

You can also look into buying strengthened tyres with thicker rubber. The Bridgestone VX Tractor range has models with up to 20% more rubber than standard tyres.

With very heavy mounted or semi-mounted tools, your tyres will be squashed by the excessive weight and will deteriorate quickly.

As well as providing increased rolling resistance, the crampons will be increasingly twisted, the tyres will heat up and the softened rubber will wear out more quickly. It is generally much more economical to equip your machine with tyres which take into consideration the real weight of your tools.

Winter is a difficult period for tyres, in particular in regions which see a lot of frost, as rubber contracts in very cold conditions.

You need to take specific precautions to preserve the quality of the rubber until the return of milder temperatures, especially if you are not using your machinery during several months.

During the winter when your farming activities are interrupted, store your tyres in the best conditions to avoid rapid deterioration.

If the tyres remain on the machine: the full weight of the tractor will be placed on one point of the tyre during a long period, which will distort the tyre’s internal structure. Remove as much weight as possible from the machine and over inflate your tyres by around 0.5 bar to provide it with the best resistance to the weight. From time to time, weather permitting, we advise that you drive your tractor for a few minutes to change the pressure points.

Tyres on their sidewalls,

are stored standing up

If you leave the tyres on their sidewalls, but you take them off the machine: check the pressure and adjust it to the normal pressure (1.6 bar generally). Store them standing up, preferably on shelves, but you can also store them lying down in a dry area.

If you inflate your tyres with water to ballast your tractor: don’t forget to add some anti-freeze to avoid the liquid freezing. If not, the water will freeze in the tyre and increase in volume, causing irreparable damage to the tyre structure.

Finally, if you store your tyres without the sidewalls: it is mandatory to store them vertically and to turn them regularly to avoid marking. We advise against storing them flat for a long time as this would distort the casing and damage them permanently.

Check and inspect

your tyres after the winter

After the winter break, it is strongly recommended to inspect your tyres to check that they are in good condition.

Any visible cracks indicate that the tyre has spent too long on in one position. This will weaken the casing considerably.

In the most serious cases, it is necessary to change the tyres, as there is a real risk of blow-out.

To take it further and increase the profitability of your farm, Bridgestone agriculture has prepared a free, detailed eBook which explains the essential role of the farming tyre on your productivity.

The most people who have read this article have also read the following articles, which are listed below in order of popularity:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

BRIDGESTONE EUROPE NV/SA

AG Department

Leonardo Da Vincilaan 1

1930 Zaventem | Belgium

Our regional office:

Athena Drive, Tachbrook Park

Warwick CV34 6UX

United Kingdom