Your agricultural tyres improve your productivity, and as you know, in order to get the best performance from your tractor, harvester or sprayer tyres and extend their service life, you need to make sure their pressure is correctly adjusted based on how they're used.

However, did you also know that improper storage (even for a short period of 1 or 2 months) can also prove highly damaging and expensive?

This means you also need to take care of your equipment even when it's not in use, be it seasonal tyres or your tractor over the winter months.

It would seem logical that tyres only get worn when they're actually used. But you should be aware of the fact that extended periods of non-use, as is the case with harvesters and seasonal sprayers, can cause significant damage to your tyres. When a tyre is not in use, it is subjected to static forces that could lead to permanent deformation of the casing.

Furthermore, rubber as a material is sensitive to its environment, and can be damaged if the tyres are stored in poor conditions. Therefore, to limit the impact of downtime on your equipment, you must abide by the best storage practices for agricultural tyres.

Prior to storage, tyres must be cleaned thoroughly to remove all soil residue and stones caught in the rubber.

Water ballasted tyres must be emptied.

You can then carry out a full inspection of the state of your tyres:

Once your tyres are clean and dry, wrap them in an opaque waterproof sheet to protect them from dust, sunlight and moisture, and make sure they are not in contact with the ground.

Tyres must be stored in a clean and dry place where the temperature remains roughly constant, as sizeable temperature fluctuations can degrade the rubber.

Choose a location away from electrical devices and assembly areas to avoid any accidental damage to your tyres.

Ideally, you should chock the vehicle and slightly deflate the tyres. If this is impossible or too difficult (for large harvesting machines, for example), off-load the machine as much as possible and increase the tyre pressure by 0.5 bar above the normal working pressure.

If you have several types of wheel for the same vehicle (such as narrow and large wheels for a sprayer, or wheels intended for twinning), the unused wheels can be stored standing or flat, but above all must be kept at their working pressure.

Preferably store the tyres standing to avoid deformation to the casing (which would render them unusable) and ideally on suitable shelves if you have any. They may be stacked, but only for very short periods of time.

Before dismantling, remember to mark the position of the tyres so that, when you re-mount them, you can either put them back in the place or swap the left and right sides depending on the wear.

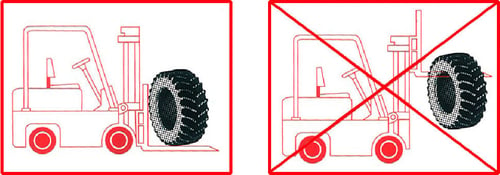

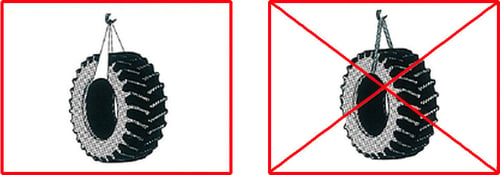

It would be such a shame to damage your tyres by handling them carelessly, so make sure to use suitable lifting equipment so as to not damage the beads. Try to use flat fabric slings or forklifts with rounded edges.

Regularly moving your tyres will help reduce the negative impact of long periods of storage and limit the appearance of small superficial cracks, which are a sign the rubber is deteriorating.

It is recommended that tyres left on the vehicle be moved at least once every three months. Dismantled tyres being stored standing should be rotated one quarter-turn every month to minimise deformation.

After a long period of inactivity, inspect your tyres for damage before re-mounting them, and adjust their pressure in accordance with their desired use.

To learn more and boost your farm's profits, Bridgestone Agriculture is offering you a free, detailed eBook that explains the essential role your agricultural tyres play in your productivity.

The most people who have read this article have also read the following articles, which are listed below in order of popularity:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

BRIDGESTONE EUROPE NV/SA

AG Department

Leonardo Da Vincilaan 1

1930 Zaventem | Belgium

Our regional office:

Athena Drive, Tachbrook Park

Warwick CV34 6UX

United Kingdom