We often focus on excessive tyre slip, but did you know that a minimal amount of slip is essential for optimal working?

This figure varies depending on the type of soil and weather conditions, and if it's too high you will end up using 20% more fuel by smoothing out the bottom of furrows and reinforcing the ploughing tread.

It's therefore necessary you can accurately calculate the rate of slip, and that you can do it in the field with your tractor without any kind of special measuring devices. This article will teach you the easiest way to identify your rate of slip, so you can be sure you're getting the best performance out of your tractor.

To better grasp the benefits of having the perfect degree of slip, you need to understand that your tyres are the go-betweens that transfer the power from your tractor to the ground. For this reason, they are of utmost importance to your work.

The lugs (or lugs) on your tyres penetrate the ground and push against the earth, compressing it until there is enough resistance to transfer the torque to the rim.

The ground's point of resistance can vary tremendously depending on the soil composition and weather conditions, and it's this resistance that allows the tyre to slide on the ground and corresponds to your slip.

Your slip ratio is lowest when driving on a dry asphalt road. In this case, the thickness of the lugs or lugs is not used, and instead it's the rubber surface of the tyre that will deform to mould to the micro-roughness of the ground, a phenomenon known as indentation.

The road surface is made from a variety of aggregates (pieces of crushed rock, gravel, sand) embedded in bitumen (tar). These aggregates protrude above the surface of the bitumen, forming a roughness that varies in height and distance apart. The rougher the surface and the more flexible the tyre rubber, the more it will adhere to the floor without slipping.

Slip is low on bitumen when you drive very slowly, although it does increase with speed. Even then it's still much lower than on wet earth, but this low slip ratio nevertheless leads to maximum wear to the rubber on your tractor tyres. This is because bitumen is so hard, it acts like sandpaper against rubber.

If you drive on an asphalt road in winter and you hit a patch of black ice or hard icy snow, all of the bitumen's micro-roughness disappears and the tyre immediately loses its grip.

Potential slip is now at its maximum, and you may lose control of the tractor if you're driving at high speed or pulling a heavy load.

The tyre lugs meet very little resistance, the sand does not stick and tractive force is lost because the lugs cannot find enough purchase to capitalise on the tractor's power.

The sand will be moved from the front to the rear and the tyres will probably sink down until they come across more resistance deeper in the soil. Fuel consumption will increase drastically due to the rolling resistance, and there's a risk your tractor will get stuck if it doesn't find firmer ground deeper down.

The ground resistance decreases as it gets wetter, and it will clump together between the tyre lugs.

If the tyre doesn't find any resistance going forward, it will go downwards instead and there's a risk the tractor will get stuck in the mud.

Depending on the quality of your tyres, the flexibility of the casing, the profile of the lugs and the degree of wear, your tyre will be more or less able to remove the soil that collects between its lugs. The risk of deep soil compaction is therefore much higher when the ground is wet.

Slight slippage is essential for perfectly transferring tractive force while preserving the topsoil. The degree of slip is equal to the ground's resistance to horizontal compression of the lugs.

To know your exact slip ratio, you need to choose a field that's representative of where you'll be working, and your tractor must be used at the same gear ratio and with the same settings as normal.

1. Make a mark on the rear wheel's sidewall where it is currently in contact with the ground, and place a similar mark or marker on the ground at the same point.

2. Turn the wheel ten times while ploughing and place a marker on the ground at the point of arrival.

3. Return to the starting point and travel the same distance (between the two markers) with the plough lifted, and count the number of wheel rotations.

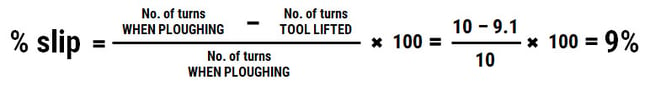

Say for example that you count 9.1 wheel rotations during the second trip with the plough lifted. The calculation will be as follows:

To learn more and boost your farm's profits, Bridgestone Agriculture is offering you a free, detailed eBook that explains the essential role your agricultural tyres play in your productivity.

The most people who have read this article have also read the following articles, which are listed below in order of popularity:

This information is intended only to make you aware of the technical and functional aspects of agricultural tires and their use. It does not allow you to make a judgment or a definitive conclusion on a given problem. Only your agricultural tire expert is able to make a technical assessment and take a final decision, case by case.

BRIDGESTONE EUROPE NV/SA

AG Department

Leonardo Da Vincilaan 1

1930 Zaventem | Belgium

Our regional office:

Athena Drive, Tachbrook Park

Warwick CV34 6UX

United Kingdom